BHP Cage Winder Upgrade

Nickel Mine

Leinster, WA

The Cage Winder at Leinster is the designated “secondary means of egress” for the mine. It consists of a “100 man” cage with counterweight. The Cage is used to transport the workforce into and out of the mine each shift to minimize transport time and maximise production time.

Key criteria - Safe, shortest change-over option

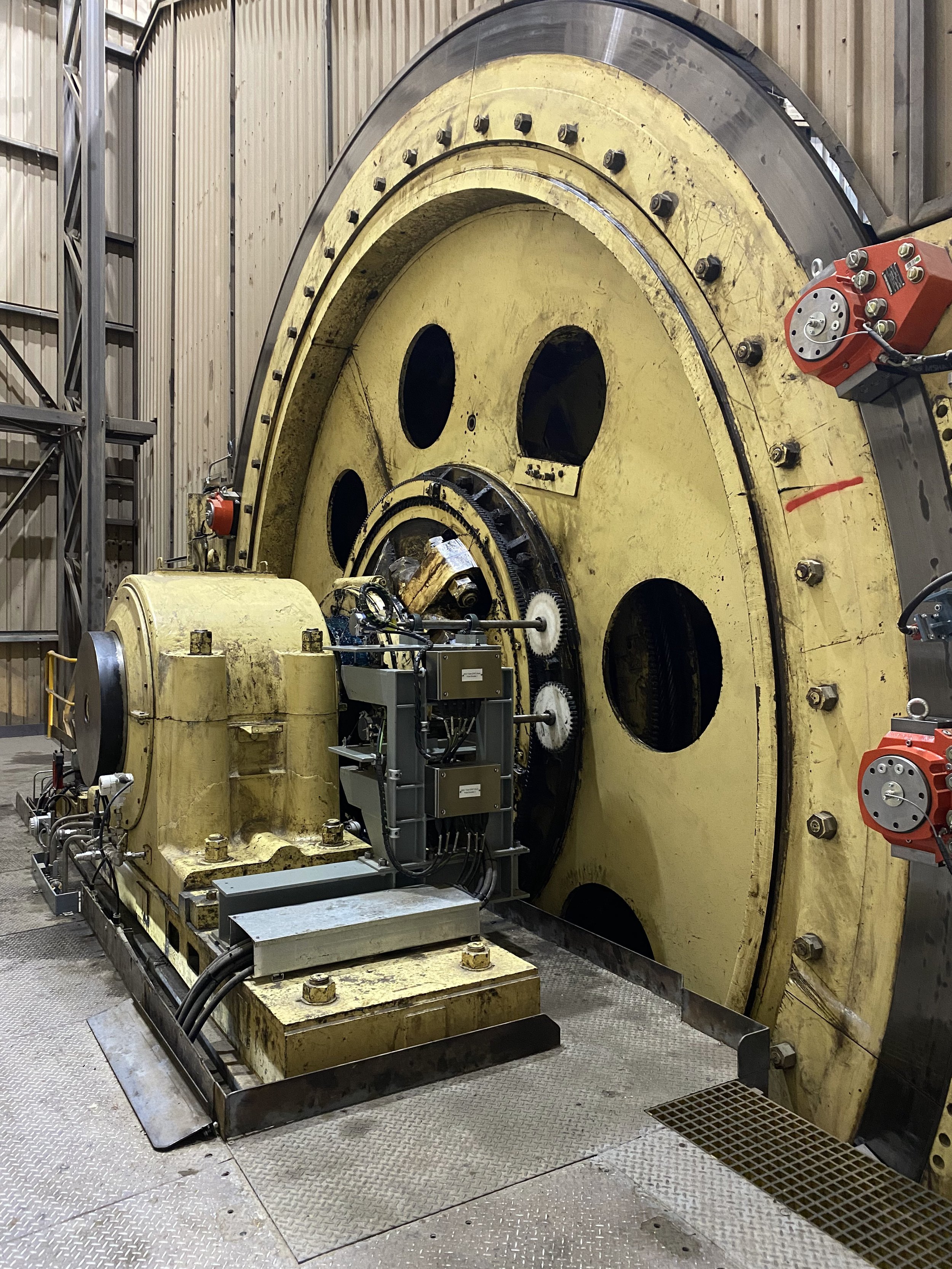

Winder - Double Drum, Cage and counterweight, Mine depth 1,100m with 13 operating level

Scope - Winder DC drive, Brake System, Control System, Safety System

How - To facilitate the shortest shutdown possible, a new equipment room was built and all equipment installed. This allowed the full winder systems to be pre-commissioned prior to shutting down the winder.

Learn more about the Project Scope here.

New Conveyance Install

Conveyance Fit Out

Driver Station Development

Final Driver Station

Before - Break and Clutch HPU

After - Break and Clutch HPU

Before - Converter Room Upgrade

After - Converter Room Upgrade

Clutched Drum Position Monitoring Encoders

Fixed Drum Position Encoders

Project Scope

-

New Safety System

Complete Brake System replacement including callipers

Control System replacement

Conveyance communication system replacement including battery charging system

HV switchboard replacement

LV MCC replacement

ELV control supply replacement

Communication network modifications for the new systems

Complete winder driver control room refurbishment

De-construction of obsolete infrastructure to free-up space required for the project

-

Manage and coordinate Winder System vendor design and delivery

Coordinate Safety System specialist design and audit work

Manage and coordinate all site installation work

Coordination of all project work with site operations to minimise project impact

Manage and coordinate all logistics for project equipment and personnel

Manage all documentation and review activities

Complete upgrade was audited and verified to AS61508 compliance

Project delivered safely with no injuries